OSP CNC turning services

Precision Contract Manufacturing & Custom CNC Machining Services

Reduce Lead Times with Done-in-One Multi-Axis Turning & Scalable Contract Manufacturing

At Ohio Screw Products, we have redefined the standard for precision manufacturing. As a premier ISO Certified and ITAR Registered contract manufacturing partner, we offer more than just machine capacity; we offer total capability. From initial concept validation to full-scale production, we provide a comprehensive custom CNC machining solution designed to meet your exact specifications.

By leveraging state-of-the-art multi-axis CNC turning, we deliver done-in-one machining services for even the most complex components. Our process is built around the philosophy that the most efficient way to manufacture a custom part is to complete it in a single setup. By eliminating the need to move parts between multiple machines, we significantly reduce handling time, mitigate operator error, and deliver superior part-to-part consistency.

Engineering Services for Custom Manufacturing

We believe that the best contract manufacturing outcomes start before the first chip is cut. Ohio Screw Products bridges the gap between design and reality with our comprehensive engineering services.

-

Design for Manufacturability (DFM): Our engineering team reviews your custom CNC machining designs to identify potential bottlenecks. We provide actionable feedback to optimize tolerances and geometries, ensuring your part is cost-effective to machine at scale.

-

Scalability: We are not just a prototype shop; we are a production powerhouse. Once your custom prototype is validated, we seamlessly transition the project to our high-volume equipment.

Versatile CNC Equipment for OEM & Contract Parts

To deliver on our promise of quality and productivity, Ohio Screw Products operates a robust arsenal of 18 dedicated CNC machining centers. We have curated a diverse equipment list that allows us to function as a versatile OEM parts manufacturer, balancing cost-efficiency with technical capability.

1. Multi-Axis & Y-Axis CNC Turning Services

The core of our custom CNC machining capability lies in our (8) SMART CNC Y-Axis Turning Centers. Traditional lathes operate on two axes (X and Z), limiting them to simple cylindrical turning. Our Y-axis CNC turning technology introduces a third dimension of movement perpendicular to the spindle. This allows us to perform live tooling operations—including off-center milling, drilling, and tapping—directly on the lathe.

-

Capacity: These centers feature a substantial 2-5/8” (66.0mm) thru-bore bar capacity, accommodating a wide range of stock sizes.

-

Complex Features: Complex CNC parts and internal/external features are generally no issue for these machines. We can execute cross-drilling, flat milling, and keyway cutting in a single setup.

2. High-Volume Production CNC Machining

For contract manufacturing projects where volume and cycle time are the primary drivers, we utilize our (5) Emco CNC 4-Spindle Turning Centers. Unlike single-spindle machines that work on one part at a time, these Emco 4-spindle turning workhorses multiply our throughput capability. They are specifically designed to handle production machining runs with exceptional efficiency, ensuring that large orders are fulfilled rapidly without sacrificing precision.

3. 4-Axis CNC Milling & Complex Geometries

To complement our turning capabilities, we operate (5) Brother CNC Vertical Milling Centers equipped with 4-axis capability. These machines allow us to tackle custom components that are primarily prismatic or require extensive milling work that goes beyond the capabilities of a lathe. Our Brother 4-axis milling services add rotational capability, enabling us to machine complex contours and multi-sided features in fewer setups.

CNC Machining Overview

Certifications & Compliance

-

ISO Certified Quality Management

-

ITAR Registered Manufacturer

-

Mil-Spec Compliant Production

Engineering Support

-

Design for Manufacturability (DFM): Optimization for cost & speed

-

Prototyping: Rapid iteration using Y-Axis & Milling centers

-

Scalability: Seamless transition from prototype to production

-

Process Engineering: “Done-in-One” workflow planning

Capacity Specifications

-

Bar Stock Diameter: Up to 2-5/8″ (66.0mm)

-

Chucking Capacity: Larger diameters supported via special work-holding

-

Tolerances: Consistently holding < 0.001″ (0.025mm)

-

Production Volume: From Rapid Prototyping to High-Volume Production

Machine Lineup (18 Centers)

-

(8) SMART CNC Y-Axis Turning Centers

-

(5) Emco CNC 4-Spindle Turning Centers

-

(5) Brother CNC 4-Axis Vertical Milling Centers

Materials Processed

-

Ferrous: All Steels, Ductile Iron Castings

-

Non-Ferrous: Aluminum, Brass Alloys, Bronze, Copper

-

Plastics: Various industrial polymers

-

Forms: Bar stock, Forgings, Castings

Specialized Capabilities

-

“Done-in-One” Multi-Axis Machining

-

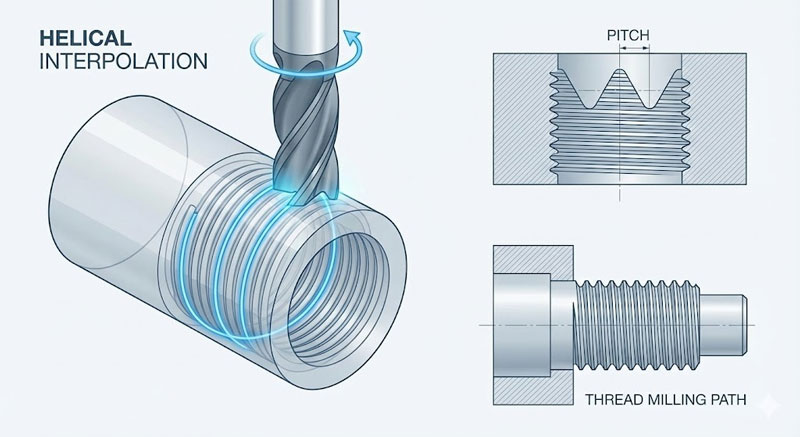

Helical Interpolation (Thread Milling ID/OD)

-

Mil-Spec Nuts with Wire-Tie Holes

Precision Machining Capabilities & Tight Tolerances

Our equipment is not just fast; it is incredibly precise. Backed by our ISO certification, we routinely achieve tolerances below 0.001″ (0.025mm) without any secondary processing. This level of precision is critical for contract manufacturing in industries where fit and function are non-negotiable.

Helical Interpolation & CNC Thread Milling One of our standout technical capabilities is the use of helical interpolation. While standard tapping can sometimes result in torn threads or limited control over fit, we utilize precision thread milling to produce threads with very tight pitch diameter tolerances.

-

Versatility: We can perform this for both ID (Internal Diameter) and OD (External Diameter) threads.

-

Quality Control: This method allows for micro-adjustments at the control to ensure every thread meets the gauge requirements perfectly.

The "One Index" Advantage: 12 Tools Working Simultaneously

The secret to our productivity lies in our ability to eliminate secondary operations. In traditional machining, a part might need to be turned on a lathe, then moved to a mill for flats, and then to a drill press for cross-holes. This adds handling time, cost, and potential for error.

At Ohio Screw Products, we utilize a full complement of attachments to produce these features all in one index of the machine.

Our multi-spindle machines can engage as many as 12 tools working simultaneously during each cycle. This allows us to complete complex features in-process, including:

-

OD Flats & Milling: Creating wrench flats or specialized profiles on the Outside Diameter.

-

Inboard Hex Shapes: Generating internal hex features for fasteners.

-

Cross-Holes: Drilling perpendicular to the main axis without removing the part.

-

Threading: Internal and external thread rolling or cutting.

By consolidating these operations, we drastically reduce cycle times. Innovation in our tooling geometry and station-by-station layout allows us to tackle parts that other shops might deem “impossible” for a screw machine.

Material Expertise: The "Copper" Specialty

Machining capacity means nothing if you cannot hold tolerances on difficult materials. A wide variety of materials can be machined in our process, including carbon steels, alloy steels, stainless steels, plastics, and brass.

However, our true differentiator is Copper. Copper is one of the specialties here at Ohio Screw Products. Known for being “gummy” and tough to machine without burrs or deformation, copper requires rigid machine setups and specific tooling expertise. Our engineers have honed the process to run copper components at high volume while maintaining excellent surface quality and dimensional accuracy.

Technical Specifications at a Glance

For engineers and buyers needing quick data, here is the breakdown of our facility’s capabilities.

| Machine Type | Quantity | Spindles | Size Range | Best For |

|---|---|---|---|---|

| ACME Gridley | 20 | 6 & 8 | 5/8" – 2" | High Volume, Large Dia, Heavy Removal |

| Euroturn (ZPS) | 5 | 6 & 8 | Up to 32mm | High Speed, Precision, Complex Geometries |

| Brown & Sharpe | 5 | 1 | Up to 1-5/8" | Medium Volume, Simple Parts, Quick Turn |

Engineering That Fits Your Needs

We don’t just take prints; we offer solutions. Our engineers are well-versed in these specific machines and processes. When you submit a request, we can quickly assess whether your part is a good fit for our multi-spindle environment or if it requires a different approach.

If you have a part designed with OD flats, cross-holes, or demanding threads, let us review it. We often find that parts currently being made on slower CNC lathes can be migrated to our multi-spindle machines for significant cost savings.

Ready to Scale?

Don’t let capacity constraints throttle your growth. Trust the experts with the fleet to back it up.

Contact Ohio Screw Products today to discuss your high-volume machining needs.