OSP Materials

Precision and Quality Begin with the Right Material — OSP Delivers Both

OSP Metals: Certified, Reliable, and Ready for Demanding Applications

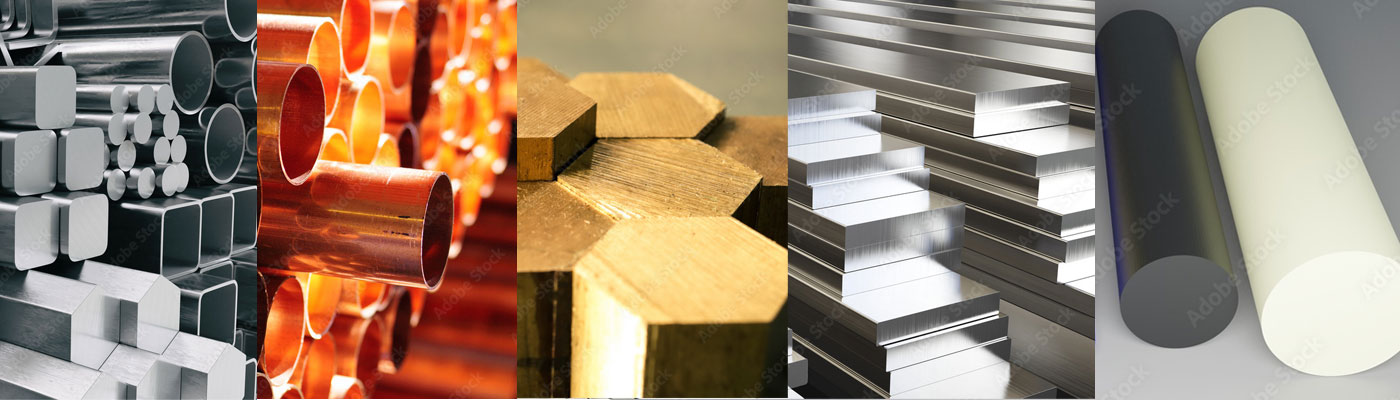

Ohio Screw Products, Inc. (OSP) combines advanced machining technology with strict material testing to deliver precision parts from both ferrous and non-ferrous metals. As a contract manufacturer, our focus is on accuracy, repeatability, and reliability. Whether you require carbon steels, stainless steels, aluminum, copper, engineered plastics, or specialty alloys, OSP provides parts that meet your specifications with quality and consistency.

OSP Material Testing & Quality Selection Process

At OSP, precision doesn’t start at the machine — it begins with the selection and testing of raw materials. Every component we manufacture undergoes a rigorous quality process to ensure that the material performs exactly as expected in your application.

Our process is built on industry-leading standards and decades of expertise. This ensures that whether you are sourcing parts for aerospace, automotive, medical, or industrial machinery, OSP delivers components that are built to last.

How OSP Ensures Material Quality

Certified sourcing – We only work with trusted, approved mills and suppliers that provide full certification and traceability. This ensures materials meet recognized standards before they even arrive at our facility.

Chemical analysis – Advanced testing verifies alloy composition, eliminating impurities and ensuring material integrity. This step guarantees the consistency needed for high-performance applications.

Mechanical testing – Strength, hardness, and ductility are measured to confirm that metals and plastics perform reliably under load.

Corrosion testing – Stainless steel, aluminum, and other corrosion-resistant materials are tested for durability in harsh conditions.

Traceability – Every batch of material is fully documented, giving customers confidence in origin, certification, and performance.

By combining material science and machining expertise, OSP ensures that every customer receives precision parts built on a foundation of strength, reliability, and certified quality.

Complete List of Materials OSP Machines

We support a wide range of industries by machining materials that balance strength, durability, corrosion resistance, and performance.

Ferrous Materials

- Carbon Steels – 1018, 1045, 1050, 1215, 12L14, 1117, 1141, 1144

- Stainless Steels – 303, 304, 316, 316L, 347, 15-5PH, 17-4PH, 416, 420, A-286

- Alloy Steels – 4140, 4340, 6150, 8620, 52100

- Steel Tubing – DOM, welded seam, seamless

- Gray and Ductile Iron

- Tool Steels – A2, D2, S7

- Powdered Metal

Non-Ferrous Materials

- Copper – 10100, 11000

- Brass – C36000, C27450

- Aluminum – 2024, 6262, 6061, 7075

- Titanium

- Inconel – 625, 718

- Nylon, UHMW, Delrin, PVC

Material Shapes

- Round Bar

- Hex Bar

- Square Bar

- Hot Forgings

- Cold Forgings

- Extrusions

- Castings

- Powder Metal Blanks

- Resin Molded Blanks

This diverse list allows OSP to machine everything from lightweight aerospace components to heavy-duty automotive parts with equal precision.

Materials in Action

Metals

- Steel – Cost-effective and versatile; used in structural, mechanical, and industrial applications.

- Stainless Steel – Corrosion-resistant and durable; ideal for medical devices, food processing equipment, and industrial machinery.

- Carbon and Alloy Steels – Offered in multiple grades; engineered for strength, toughness, and reliability.

- Aluminum – Lightweight yet strong; used in aerospace, automotive, and marine applications.

- Copper – Exceptional electrical and thermal conductivity; critical for wiring, heat exchangers, and precision components.

- Brass and No-Lead Brass – Excellent machinability and conductivity; used in plumbing, electrical, and medical components.

- Bronze – Durable and wear-resistant; ideal for bushings, bearings, and heavy-duty parts.

- Tubing – Essential for structural supports, hydraulic systems, and custom applications.

Engineered Plastics

- Acetal (Delrin®) – High strength, low friction, and excellent dimensional stability; common in gears and bearings.

- PVC – Lightweight and corrosion-resistant; used in housings, fluid systems, and protective components.

- Nylon – Strong, versatile, and wear-resistant; ideal for bushings, pulleys, and industrial parts.

Why Work with OSP?

OSP is more than a machine shop — we are a manufacturing partner trusted across industries. Customers choose OSP because we provide end-to-end machining solutions backed by certified quality.

What sets OSP apart:

-

Expertise in ferrous and non-ferrous machining – From tough steels to lightweight aluminum and engineered plastics.

-

Rigorous testing and certified material selection – Every part starts with verified, documented materials.

-

Custom parts built to exact specifications – Meeting tight tolerances and demanding designs.

-

Reliable quality and on-time delivery – Ensuring your supply chain runs smoothly.

Whether you need one-off prototypes or high-volume production runs, OSP delivers parts with accuracy, consistency, and traceable quality.

Get the Right Material for Your Precision Parts

From automotive gears and aerospace components to medical devices and industrial machinery, OSP ensures your project benefits from the right material, expertly machined. By combining certified sourcing, advanced testing, and state-of-the-art machining, OSP provides more than parts — we provide confidence.

Contact OSP today to learn how our expertise in ferrous and non-ferrous metals, engineered plastics, and specialty alloys can support your next project with proven quality and precision.

OSP Quality Commitment

Certified Materials – All metals are sourced from trusted, approved suppliers.

Rigorous Testing – Every batch undergoes chemical, mechanical, and corrosion testing.

Full Traceability – Complete documentation ensures quality at every stage.

Exacting Standards – Parts are machined to meet tight tolerances and customer specifications.