Quality You Can Measure: Inspection & Verification at OSP

Precision CNC machining and multi-spindle screw machining require more than capable machines—they demand reliable inspection systems that verify critical features quickly, consistently, and with traceable accuracy. Our Quality Department combines advanced metrology, non-contact vision systems, automated inspection, and calibrated gaging to support tight tolerances and high-volume production.

Quality Inspection Equipment

Dimensional Metrology & 3D Inspection

Zeiss CMM: OI-322 (with Calypso Software)

Our Zeiss coordinate measuring machine (CMM) delivers high-accuracy 3D inspection for complex CNC components. It’s used to verify GD&T, true position, feature relationships, and critical dimensions for first articles and ongoing production validation. Calypso software enables programmed inspection routines for excellent repeatability and consistent reporting.

Non-Contact Vision & Rapid Measurement Systems

Keyence LM-1000

A fast, non-contact optical measurement system ideal for high-volume turned parts. The LM-1000 measures key dimensions such as lengths, diameters, and radii quickly with minimal operator variation—perfect for speeding up in-process checks and production sampling.

Keyence IM-6020

An automated image-based inspection system that captures and measures multiple features in one routine. The IM-6020 supports efficient first-article inspection and production checks by improving measurement consistency and reducing inspection time on multi-spindle and CNC components.

Keyence XT-024

A non-contact measurement system used for rapid verification of critical dimensions and inspection documentation. It helps streamline inspection workflows, especially when quick, repeatable checks are needed without contacting the part surface.

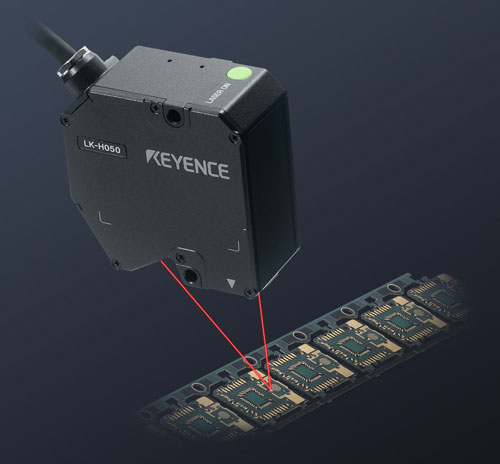

Keyence LK Series Cameras paired with 100% Automated Inspection Machines

A non-contact measurement system used for rapid verification of critical dimensions and inspection documentation. It helps streamline inspection workflows, especially when quick, repeatable checks are needed without contacting the part surface.

Production Gauging & In-Process Verification

Mitutoyo Digital Gauges

Precision digital gaging tools are used for quick, consistent measurement of common turned and machined features. These tools support efficient in-process inspection to keep production centered and stable during long runs.

Brown & Sharpe Digital Gauges

Reliable digital measurement gages used for repeatable dimensional checks on the shop floor and in final inspection. They help verify diameters, lengths, and critical characteristics during high-volume manufacturing.

Mahr & Edmunds Air Gauges

Air gaging systems that provide exceptionally repeatable measurement of close-tolerance bores and diameters. Air gages are an excellent fit for multi-spindle screw machining—supporting fast inspection cycles with strong repeatability for tight ID/OD requirements.

Thread Measurement & Verification

Thread Check Variable Thread Depth Gauge

A dedicated gauge for confirming thread depth and functional engagement. This helps ensure tapped features meet print requirements and assemble correctly—reducing the risk of shallow threads or insufficient engagement.

Fowler QM Variable Thread Gauge

An adjustable thread gauge is used to verify thread acceptability across multiple thread sizes and specifications. It supports efficient thread inspection for both in-process checks and final validation.

Optical Profile & Shop-Floor Inspection Support

Optical Comparators (Quality, Shop Floor, and Tool Room)

Optical comparators magnify and project a part’s profile for quick measurement and visual verification. They’re especially useful for radii, angles, chamfers, undercuts, and thread forms—making them a practical tool for fast checks across departments.

Material & Surface Verification

Rockwell Hardness Tester

Optical comparators magnify and project a part’s profile for quick measurement and visual verification. They’re especially useful for radii, angles, chamfers, undercuts, and thread forms—making them a practical tool for fast checks across departments.

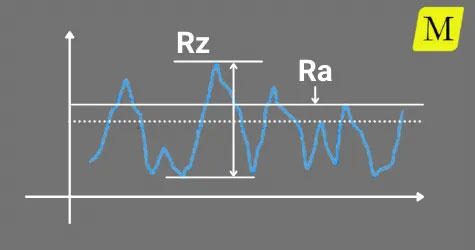

Surface Finish Analysis

Optical comparators magnify and project a part’s profile for quick measurement and visual verification. They’re especially useful for radii, angles, chamfers, undercuts, and thread forms—making them a practical tool for fast checks across departments.

Calibration, Accuracy & Traceability

Onsite Gauge Lab with In-House Calibration Capabilities

Optical comparators magnify and project a part’s profile for quick measurement and visual verification. They’re especially useful for radii, angles, chamfers, undercuts, and thread forms—making them a practical tool for fast checks across departments.